Experience summary of flight defense application scenarios

In recent years, Qingyu has carried out field application and efficacy investigation of flight control. The factors that need to be considered and some successful experiences in the application of flight defense are summarized.

Next, the effects of different spray ways on deposition amount are mainly introduced. In 2019, a spray test for cotton aphid control was carried out in Xinjiang. A comparison was made between two machines. One was a self propelled boom machine, with a height of 50cm, a liquid tank of 2000kg, and an amount of 50kg for an acre of land. However, the height of UAV from crop canopy is 1.2m, and the conventional dosage is 1.2kg per mu, and the highest is 1.6kg. Therefore, when the height of cotton plant is different and the water consumption is very different, the deposition amount of medicine solution is obviously different. In the case of little water consumption for flight control, how to increase the droplet deposition on the lower leaves of crops is a problem worthy of consideration and exploration.

The test results show that the top and middle layers of boom boom unit are ideal, but only the top of the unmanned unit receives droplets, and the middle layer is not ideal.

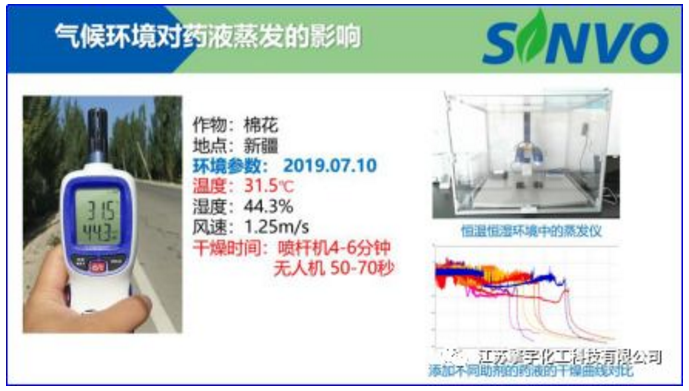

The other is the influence of environment and climate on the evaporation of medicine solution. The main reason is that UAVs are operating on the basis of the water consumption of the traditional spray mode of 1/30. At this time, the moisture and anti evaporation ability of the liquid medicine is especially important. That is equivalent to the original 30 droplets on the blade, now there may be only one droplet, so it is necessary to effectively maintain the anti evaporation performance of the solution on the leaf surface.

On the test day, the measured humidity was only 44% after rain. We compared the water consumption of 50 kg per mu of boom sprayer. The drying time of liquid medicine on the leaves was about 4-6 min, while that of UAV was only 50 s to 70 s, and the liquid was completely dried. Therefore, compared with the traditional application method, the drying speed of the solution in the field is far beyond our imagination. In this case, the anti evaporation ability of the liquid medicine or the anti evaporation performance of the auxiliary agent is particularly important.

At present, we have introduced the instrument on the right side to do this test. Through this instrument, we can screen the dryness of the liquid medicine added with different additives. This instrument is very precise and can accurately judge the anti evaporation ability of the liquid medicine.

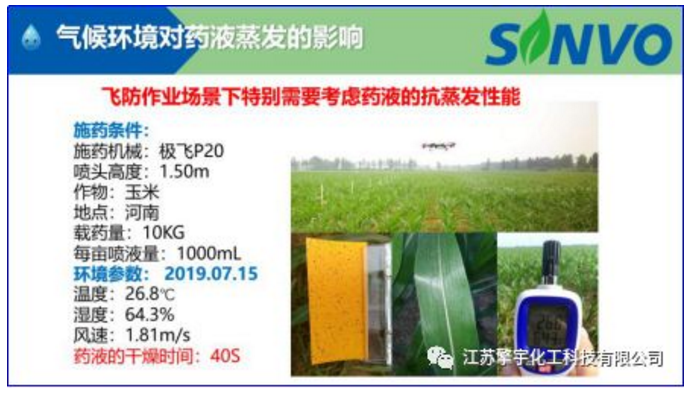

This is the situation of corn field operation in Henan Province. At that time, the temperature was 26 ℃, the environmental humidity was 64.3%, but the wind speed reached 1.8m/s, and the drying time of the liquid medicine on the leaf surface was only 40s. Under the flight prevention scene, the drying time of the liquid medicine had broken the unit of minutes as the limit. In order to achieve good efficacy, it was in a race with time. How to effectively penetrate the surface of plants, penetrate or penetrate into plant tissues in a limited time, is me What we need to think about.

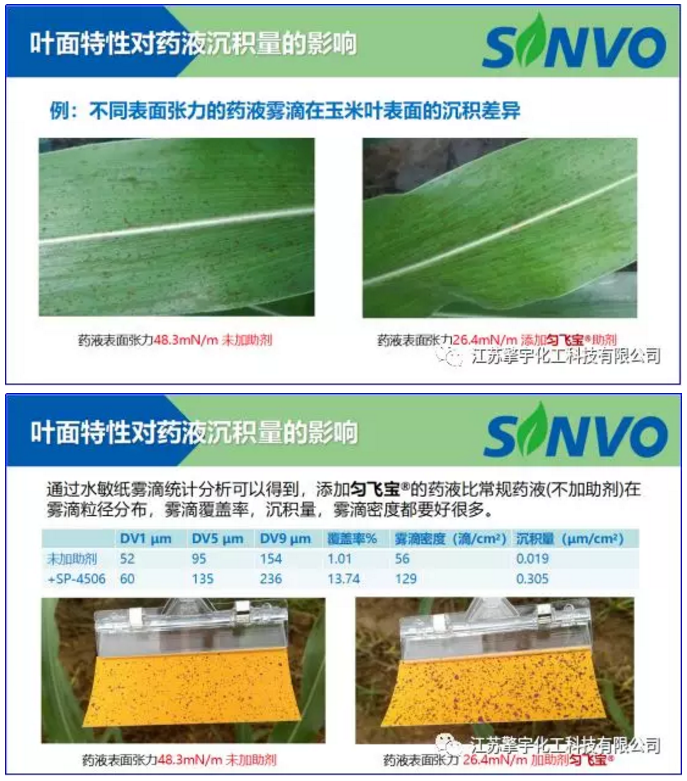

The surface tension of different crops with different leaf surface characteristics is different. There are some objective differences of different surface tension on the same corn leaves. By adding additives, the coverage rate and density of droplets can be significantly improved, and the deposition amount of liquid medicine has been significantly improved.

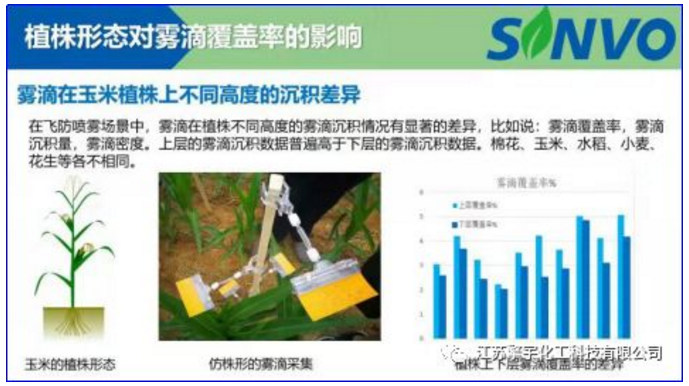

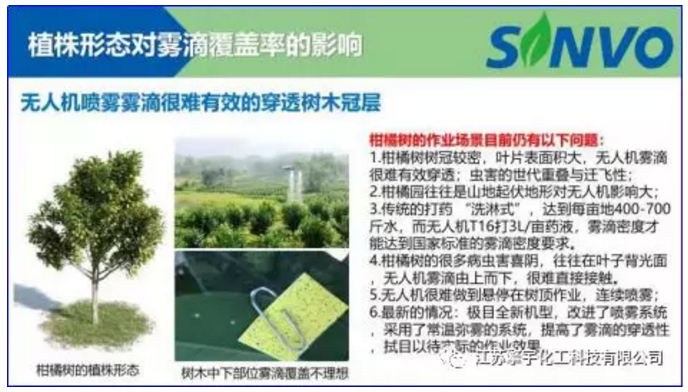

In addition, the effect of plant morphology on droplet coverage should be considered. In the past, the artificial application can be adjusted at any time, but in the flight control operation, the plant morphology of different crops is different, the planting density of plants is also different, the location of diseases and insect pests is different, and the water consumption is also quite different. Therefore, when designing the package, we need to consider these factors according to local conditions and pay attention to the actual spray effect.

Through the collection of droplets at different heights, the difference is obvious. Taking maize as an example, the plant height is relatively high. Through a plant like scaffold for collection, the histogram on the right shows that the coverage rate of the lower layer is basically lower than that of the upper layer. In the future, how to improve the penetration of the canopy dense crops in our flight control operations? This is worthy of our study, including UAV enterprises and their spraying systems.

Plant morphology is the most important factor affecting droplet coverage. At present, citrus is the first fruit planting area in China, and its total output value has ranked first in the main economic crops. Citrus crown is relatively dense, and most of them are planted in mountainous areas, and the planting area is relatively large, so the water consumption of UAV is difficult to penetrate the surface layer of tree crown effectively. In general, many pests on citrus trees are overlapping generations and migrating.

The traditional medicine uses the "washing type" operation, the water consumption of UAV flight control is small, this difference is very huge, which is one reason why the application and promotion effect of UAV in Citrus area is not ideal. The first is related to the continuous working ability of the aircraft itself. In addition, the prevention effect of UAV is not up to our expectation.

Diseases and insect pests of citrus trees are often caused by the back light of leaves. However, the application mode of UAV is from top to bottom, so it is difficult to directly contact the damaged parts. In addition, UAV is difficult to achieve intelligent hovering operation, often continuous spray, resulting in the waste of liquid. Even if some of them can do hovering operation, their batteries are difficult to support large area flight effectively. It's hard to really improve efficiency. During the recent exchanges with the pesticide industry colleagues, I learned that a new UAV was launched in the extreme. He improved the spray system and adopted the fog at room temperature. The improved spray system improves the penetration of droplets. The picture shows a new model in 2020, which is specially designed for the use of citrus trees.

In the application of rice field, due to the high humidity of paddy field, the water sensitive paper is very easy to aging in the process of droplet collection. We also made some optimization and adopted some professional fixtures. At the same time, due to the high planting density of rice, especially the control effect of root and stem base parts needs to be improved, and this problem also exists in wheat field, so UAV spraying still needs to be improved.

In Pepper application, UAV is more suitable, mainly because its plant shape is relatively short, there is a certain distance. So we need to consider the drift of droplets and anti evaporation. These problems can be controlled by adding barrel additives.

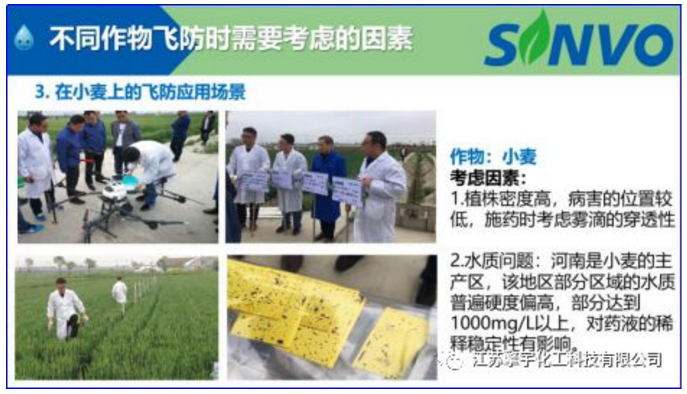

For wheat, we found that the main problem is water quality. In the main wheat producing areas in China, such as Henan, the hardness of local water is generally high, which has a great impact on the dilution stability of flight control solution. Although the diameter of D50 μ m is less than 50 μ m, the hard particles may not precipitate rapidly when the diameter of D50 μ m is less than 50 μ M. This has a great influence on the diffusion of liquid medicine.

Cotton has been introduced just now. What factors need to be considered in UAV operation? Especially in the use of defoliant this year, there are still many problems in the application mode of UAV. It can be imagined that the traditional water consumption is very large, and both deturon and ethephon can be effectively absorbed by the leaves. UAV flight control is a high concentration spray. First, whether the leaves can be effectively absorbed; second, whether the use of high concentration of plant regulators will affect the ripening of cotton peach? Whether the traditional additives can continue to be used? In the UAV flight control conditions, due to the huge difference in water volume, can the traditional alkyl ethyl sulfonate still meet the control needs of defoliants? We think that the need area It is necessary to develop special additives suitable for UAV application separately. Through the cotton defoliant practice this year, we think that the answer is very clear now. UAV spraying must use special flight control additives to help the chemicals play a role.

At the same time, we also carried out the flight control experiment of Welsh onion, which mainly considered the particularity of the plant. From the perspective of plant type, the onion leaves are tubular and receive fog drops on the side. Moreover, there is a thin wax layer on the surface of onion leaves, which is difficult to be effectively wetted. This is a problem that must be given priority in the flight control operation of such crops as scallion or onion. How to improve the wettability and prevent the rebound and slide when the liquid medicine contacts with the hydrophobic interface.

The application scene of corn has been introduced just now, so I will not repeat it. Because of the low plant shape of peanut, the factors of spraying environment, temperature and humidity should be considered, and the evaporation loss in the process of space transfer should be considered.

Finally, we will introduce the application scenarios of flying prevention in rice and shrimp fields. It is reported that China's lobster industry will have an output value of about 300 billion yuan by 2019. In recent years, more and more shrimp paddy fields have been planted in Qianjiang of Jiangsu, Anhui and Hubei provinces. However, the application of drugs in shrimp paddy fields, especially flight control agents, additives and related products, has its own particularity.

First, the toxicity of the formula must be considered, and the safety of lobster must be considered. At the end of this experiment, the limit dose experiment of high concentration medicament in lobster pond proves that it is safe. Secondly, in order to reduce the toxicity of the whole formula system, besides acute toxicity, we should also pay attention to the control of rice diseases by pesticides, which can not cause adverse effects on the growth and development of crayfish. Thirdly, the shrimp paddy field will definitely be the world of flying prevention in the future. Because the structure of shrimp paddy field is very special, there is a moat around the field like a moat. It is very difficult to enter the field with traditional agricultural machinery or artificial. In order to meet the habitat requirements of crayfish, the depth of water is far greater than that of ordinary field ditches. Therefore, in the rice control season, only nobody is left The machine is the most convenient way to apply medicine.

Through nearly one or two years of exploration, we have accumulated a lot of experience in the application technology and safety of flying prevention in shrimp paddy field. It should be said that we have a more mature application scheme.